In today’s world, where machines dictate speed and mass production has become the norm, we at Cotto Rustic choose a different path – a conscious return to the roots of true craftsmanship. Our terracotta tiles are born from a meticulous, traditional process shaped by experience, patience, and genuine handwork.

A Glimpse into a Centuries-Old Tradition

Some things stand the test of time – not because they are flawless, but because they are authentic.

Our terracotta tiles are more than just flooring: they embody knowledge and skill passed down through generations.

What once began in our grandfather’s workshop lives on today with the same care and passion. Every gesture, every technique, every detail is rooted in our family’s long history – carried by the desire to create something enduring.

At Cotto Rustic, we see ourselves not just as manufacturers, but as guardians of an ancient craft.

A craft that takes time, demands dedication, and comes from the heart.

Shaped by Hand – Every Tile Is Unique

It all begins with pure, locally sourced clay. Mixed only with water – without any artificial additives – it forms the basis of our tiles. The soft clay mass is then shaped entirely by hand, step by step, with great care and precision. In this way, each tile develops its own character. Small irregularities in shape and surface are not flaws, but rather a testament to true craftsmanship.

Naturally Dried – With Sun and Time

After shaping comes a particularly important step: drying. With us, this happens exclusively in a natural way – slowly and evenly in the open air, often over several days. This phase is crucial to ensure that the tile does not crack or break later during firing. Sun, wind, and time work hand in hand here.

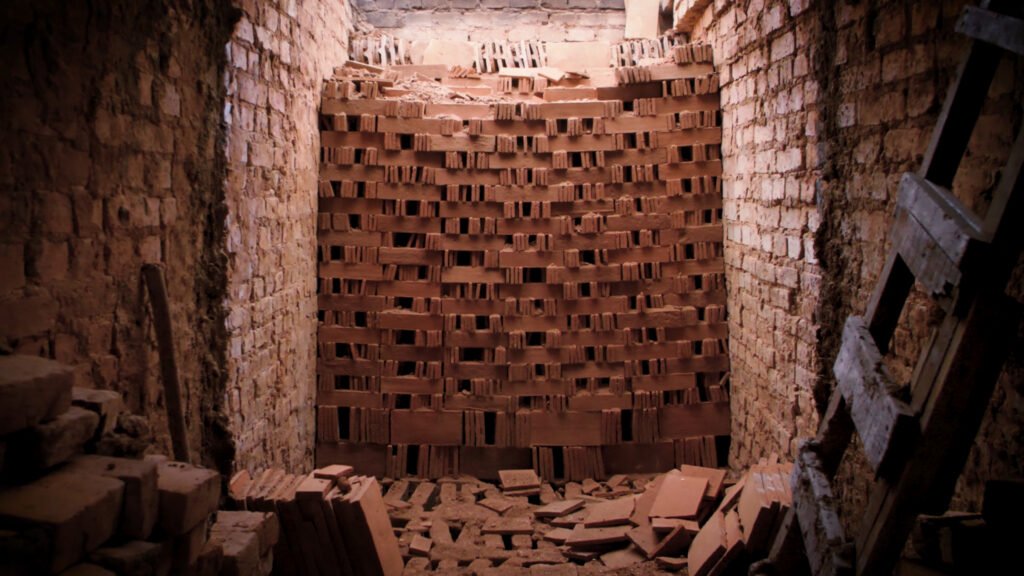

The Final Touch – Firing in the Traditional Wood Kiln

Once the tiles are fully dried, the most intense part of the process begins – firing in the traditional wood kiln.

This process requires not only experience but also patience and a keen sense for temperature and timing. The fire is lit by hand and carefully maintained over several days.

First, the kiln is slowly brought up to temperature over the course of 24 to 36 hours. The actual firing then takes place at around 1,000 °C – without digital controls, guided solely by the trained eye and skilled hand of the kiln master.

After firing, the kiln requires another two to three days to cool down gently. This careful cooling process is essential to avoid tension within the material and to ensure the tiles’ stability.

Wood firing not only gives our tiles their remarkable durability but also their characteristic variety of colors – from warm yellows to soft oranges and deep, rich reds. Each batch is unique, shaped by flame, time, and handcraft.

This process requires not only experience but also patience and a keen sense for temperature and timing. The fire is lit by hand and carefully maintained over several days.

First, the kiln is slowly brought up to temperature over the course of 24 to 36 hours. The actual firing then takes place at around 1,000 °C – without digital controls, guided solely by the trained eye and skilled hand of the kiln master.

After firing, the kiln requires another two to three days to cool down gently. This careful cooling process is essential to avoid tension within the material and to ensure the tiles’ stability.

Wood firing not only gives our tiles their outstanding durability but also their distinctive spectrum of colors – from warm yellows to soft orange shades and deep, rich reds. Each batch is a one-of-a-kind creation, shaped by flame, time, and handcraft.

Selection with a Trained Eye

After the firing process, every single tile is inspected and sorted by hand. Only those pieces that meet our high standards of quality, character, and feel make their way to our customers. The rest is reused or recycled – fully in line with our sustainable philosophy.

The Result – Terracotta Tiles with Soul

What remains in the end is not just a tile – it is a piece of true craftsmanship. Our terracotta tiles tell stories: of earth, fire, air, and water; of people with a passion for their craft; and of spaces that gain warmth, depth, and character through them.

🎥 A Look Behind the Scenes: Our Production Process on Video

Would you like to see how our terracotta tiles are really made – from the very first hand movement to the final flame in the wood kiln?

Or discover our short film on YouTube:

👉 Watch the video now

If you would like to see how our handmade terracotta tiles look in real spaces, take a look at our inspirations and customer projects.