In contemporary architecture, material selection is often made early in the design process. The architectural quality of a project, however, rarely becomes apparent in this initial decision. It emerges only during execution — in the details of connections, transitions, and constructive solutions. It is at these moments that projects are ultimately decided.

Within this context, terracotta tiles cannot be understood as neutral floor or wall surfaces. They are a material with their own logic, responding to climate, use, and time. Their application in architectural detailing requires understanding — but in return offers a depth and durability that industrially manufactured systems rarely achieve.

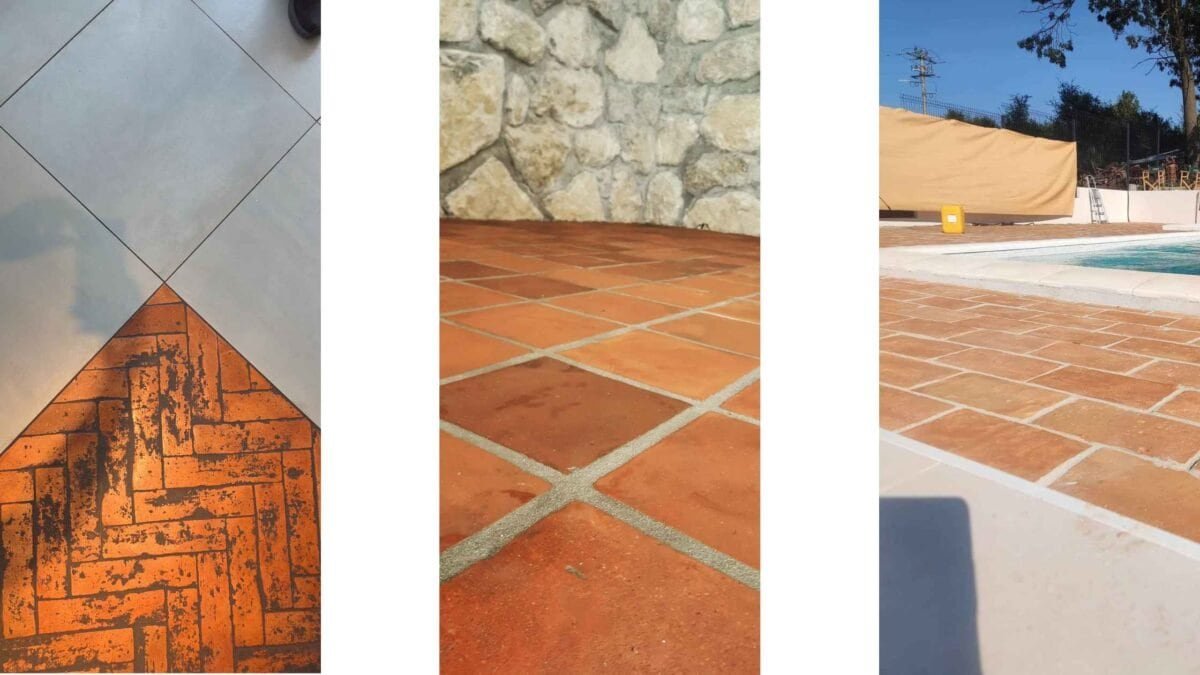

Handcrafted Terracotta Tiles and the Question of Tolerances in Architectural Detail

Tolerances as an Integral Part of the Material

The production process of handcrafted terracotta tiles involves manual forming, natural drying, and firing in traditional kilns. This process does not aim for absolute standardisation. Natural variations in dimensions, thickness, surface texture, and colour tone are inevitable — and an integral part of the material.

In planning practice, these tolerances are often viewed as a problem to be eliminated. In reality, however, they represent a material-related condition that must be integrated into the detailing. When handcrafted terracotta tiles are planned according to the same logic as industrial ceramics, a conflict inevitably arises between expectation and actual material behaviour. When their properties are consciously taken into account, calm, stable, and durable details emerge.

Joint Width as a Tool for Accommodating Dimensional Variations

Tolerances should be addressed already at the stage of detailed planning — particularly through joint width and laying pattern. Instead of “correcting” formats on site, dimensional deviations are distributed evenly across the surface. In this way, irregularities are no longer perceived as defects, but as a controlled component of the architectural expression.

Practical note:

The joint width should be greater than the maximum expected dimensional deviation of the tile. If tiles exhibit variations of approximately ±3 mm, a 5 mm joint appears visually tense. A joint width of 8–10 mm, by contrast, allows tolerances to be absorbed evenly and results in a calm overall appearance of the surface.

Between Material and Detail Lies the Decision

In architectural practice, many problems arise not from incorrect material selection, but from a failure to translate the material into constructive detail. Handcrafted tiles do not demand complex solutions — they demand consistency.

Those who understand and accept their properties simplify detailing. Those who attempt to control or “correct” them create complexity, tension, and long-term damage. Good details do not emerge from maximum precision, but from a precise understanding of the material.

Floor–Wall Connections with Handcrafted Terracotta Tiles

The transition between horizontal and vertical surfaces is among the most sensitive architectural details. With industrial materials, a hard, precisely defined line can function. With handcrafted terracotta tiles, however, this approach frequently leads to tension and visual conflict.

The material is vapour-permeable and hygroscopic. It responds to changes in indoor climate, humidity, and temperature. A floor–wall connection that ignores this behaviour will, over time, become a problematic area. A good detail does not attempt to control the material, but rather enables defined and controlled behaviour.

The hygroscopic behaviour of porous building materials has long been documented in building physics, including research conducted by the Fraunhofer Institute for Building Physics (IBP).

Practical note:

The connection should not be executed as a rigid, fully sealed line. A minimal constructive tolerance is necessary to accommodate material-related movement. Rigid connections frequently lead to microcracks or visible stress along the joint line.

Transitions Between Handcrafted Terracotta Tiles and Other Materials

Contemporary interiors almost always combine multiple materials. Terracotta meets wood, natural stone, concrete, or microcement. Each of these materials exhibits its own thermal and hygroscopic behaviour.

In transitions to other materials, terracotta requires a different detailing strategy than industrial systems.Quality does not arise from concealing differences, but from the conscious articulation of those differences. A functional transition preserves the inherent logic of each material and relates them to one another.

Practical note:

The greater the differences in the physical behaviour of the materials, the more clearly the transition must be articulated. A controlled gap or a subtle expansion joint allows each material to respond according to its properties without building up stress.

Joints and Movement in Handcrafted Terracotta Tiles as an Architectural Tool

Joints as Scale and Rhythm of the Surface

With handcrafted terracotta tiles, joints and expansion joints are not merely technical necessities. They influence rhythm, scale, and the legibility of a surface. Joint width, texture, and colour become active design elements.

The industrial logic of minimal joints works only to a limited extent with terracotta. Handcrafted terracotta tiles require space to express their materiality. Properly dimensioned joints calm the surface and connect individual elements into a cohesive whole.

Joint Colour and Architectural Calm

Practical note:

Strongly contrasting joints emphasise the grid and make the joint itself the dominant element. Joints in a tone similar to the tile — or in a warm, terracotta-related colour — shift the focus to the material and the overall surface effect. In most architectural applications, a warm, neutral joint leads to a calmer and more durable result.

When Irregularity Becomes a Design Quality

A common mistake in working with terracotta is the attempt to conceal its irregularity. These surfaces are never completely identical — and that is precisely their strength.

The difference between a restless and a controlled surface does not lie in the degree of perfection, but in the quality of the detail. When tolerances are accepted and consistently integrated into the planning process, depth and visual calm emerge.

Practical note:

Irregularities should not be corrected selectively. They must be consistently accepted and distributed across the entire project. Architectural control is achieved not by eliminating differences, but by consciously organising them.

Typical Planning Errors with Handcrafted Terracotta Tiles

Industrial Planning Logic as the Most Common Source of Error

Problems usually arise from false assumptions: terracotta is planned like industrial ceramics, tolerances are ignored in the detailing, and the material is expected to behave in ways that do not correspond to its nature.

When handcrafted terracotta tiles are used without an understanding of their material logic, problems almost always manifest in the details of connections and transitions. These issues are not inherent to the material itself, but are the result of inappropriate planning.

Practical note:

Details should be derived from real material behaviour, not from idealised geometry. When terracotta is understood as an active component of the project, detailing becomes simpler — and long-term stability increases.

Material-appropriate detailing also requires a fundamental understanding of material properties, as well as proper surface care and protection.

Conclusion: A Material for Architects Who Take Detail Seriously

Handcrafted terracotta tiles are not a material of compromise. They are a precise tool — provided they are understood on their own terms. Their strength lies not in standardised perfection, but in their ability to make time, use, and material honesty visible.

Connections, transitions, and joints ultimately determine the success or failure of a project. When they are developed from the logic of the material, calm, durable, and architecturally convincing solutions emerge.

In this sense, handcrafted terracotta tiles are not a material for quick solutions or schematic details. They are a material for architects who are willing to take responsibility for detail — because that is precisely where architecture begins.

FAQ – Handcrafted Terracotta Tiles in Architectural Detailing

Why are wider joints advisable with handcrafted terracotta tiles?

Handcrafted terracotta tiles exhibit material-related dimensional tolerances. Wider joints allow these variations to be absorbed evenly, reduce visual tension, and create a calmer, more harmonious surface.

How should floor–wall connections be designed with handcrafted terracotta tiles?

Floor–wall connections should not be rigid. A small constructive tolerance allows the surface to respond to changes in humidity and temperature without causing cracks or stress along the joint line.

Are narrow joints problematic with handcrafted terracotta tiles?

Narrow joints are technically possible, but they often conflict with the material logic of handcrafted terracotta tiles. They accentuate dimensional variations more strongly and frequently result in a visually restless surface.

How do transitions to other materials affect detailing?

Transitions between terracotta and other materials should be clearly and materially articulated. Differences in hygroscopic and thermal behaviour require defined transition zones in order to prevent long-term stress and damage.

What role does joint colour play in architectural perception?

The colour of the joint plays a decisive role in shaping the rhythm and legibility of a surface. Warm, tonally related joints direct attention to the material itself, while strongly contrasting joints emphasise the grid and can make the surface appear visually more restless.